Back at it after the winter ice storm that never emerged really, but for which the city shut down over the weekend.

I spent today throwing again. I think honestly I just need to keep practicing for a while and also figuring out some of the unique challenged I’m creating here. Craft as a process is often characterized by the process of finding compelling problems and then developing interesting solutions to those problems. One problem I’m running into a lot so far has to do with drying and clay shrinkage. I’m throwing very thin porcelain pieces. Porcelain generally shrinks the most of any clay because it has no large particles in it, nothing to hold the structure in place. That lack of large particles also means that porcelain is hard to trim well when it is wet. It’s gummy. On the other hand, it can be trimmed quite easily and pleasantly when it’s almost dry. In Jingdezhen, porcelain was almost exclusively trimmed when it was completely dry.

But I am trying to attach handles to these pieces using a very euro-american style of attaching a lug of clay to the side of the pot and then pulling it out into a thin strap with a very wet hand (an iconically erotic looking process). But this means that the handle is made of quite wet clay that will shrink and then pull away from the body of the pot which is quite dry already and so not doing any shrinking of its own.

And throwing so thin means that even if I solve the trimming problem, it would be quite hard to attach the handles earlier because the pulling d end up warping the still malleable clay of the pot itself.

So I’m contemplating all of that while also practicing my mug form on the wheel quite a lot. The curve is becoming clearer, things are moving (slowly) in a good direction. Handle experiments will come later in the week.

A long day of experimenting with mug shapes. I am pretty confident in the mug bodies at this point, though there seem to be two different styles developing. If they both end up making looking satisfying as they come through the kiln, one will be the studio style and the other will be a more uniquely “me” set of pots. I know I’m entirely synonymous with the pottery at this point, but I do like the idea of creating a range of pots that is properly the pottery’s and not mine. That feels like a more objective, distanced criteria to stick to and so something I can maybe be okay with staying pretty static and being an exercise in consistency.

I’ll take some pictures of that tomorrow.

I also spent a good bit of time looking at the test tiles again today. There’s almost a stickiness to the base glaze against itself. I fired a gaiwan and where glazed lid meets glazed pots, there’s an unpleasant stiffness and screeching if I try to smoothly move one piece against the other. Aesthetically I think a slightly more matte glaze will be better for the teaware in any case and that should solve some of that problem, but I need to look into this a bit more. Sometimes glass on glass is incredibly smooth and satisfying, so I don’t quite understand what the property is here that’s causing this stiffness. If anyone knows anything about how this works, I’d love to hear about it.

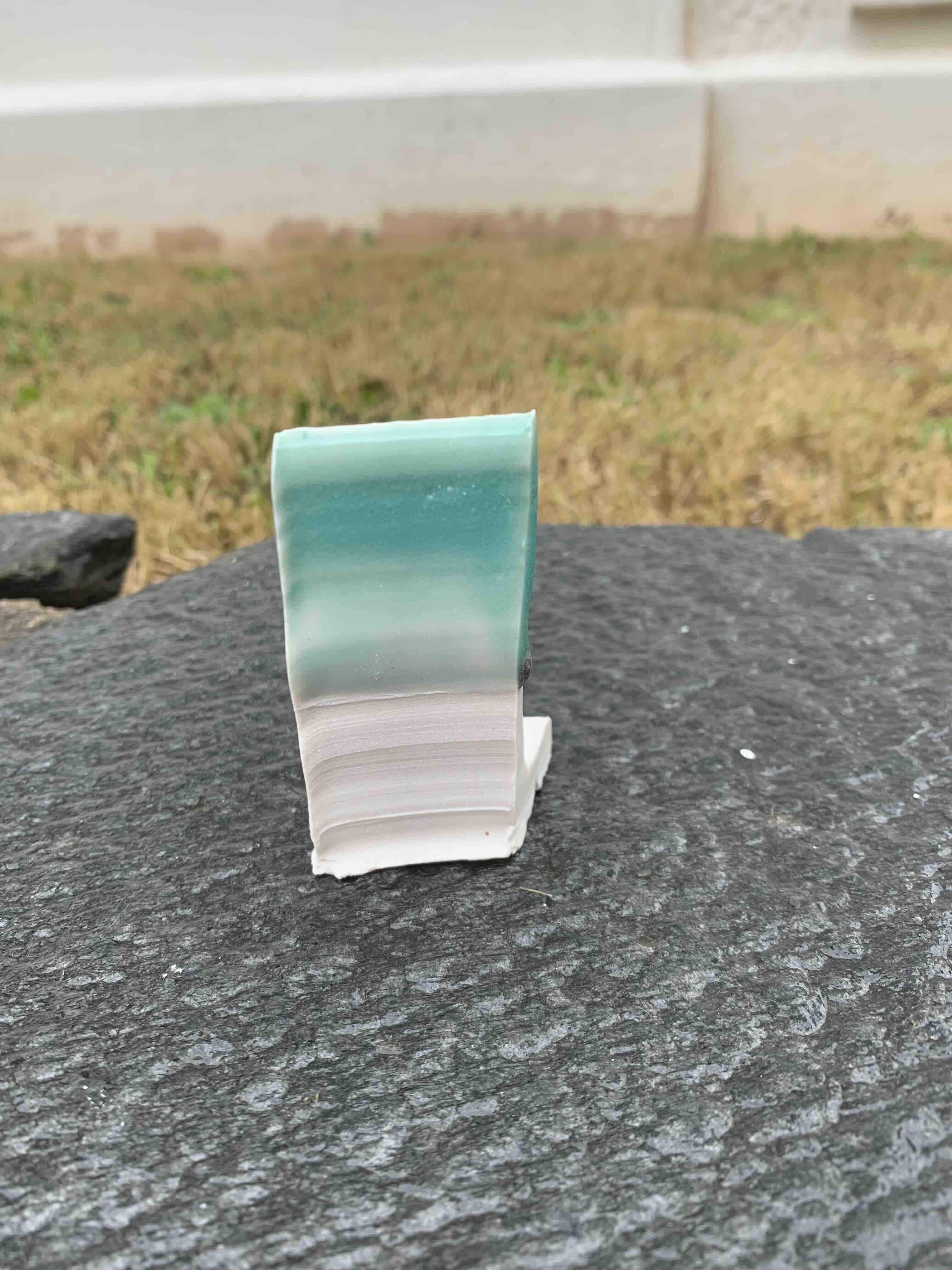

Here are a few pics of glaze test tiles:

cobalt blue

copper blue

iron yellow

matte glaze - oversaturated with Wollstonite

the silicon carbide attempt at a copper red. Way too much though and it got kind of boiled looking!

Glazes came out of the kiln. Some were really lovely. The base glaze that I’m using doesn’t run. It has a beautiful bubble structure in it as well which isn’t incredibly visible against the white porcelain but it’s a nice detail close up and might be more visible if I end up doing some under glazing or slips.

I have some cobalt blues that turned out quite nicely as well as some copper greens. Rutile made some less pleasant creamy oranges that are just sort of outside the range of what I want. I added a lot of wollastonite to the base for an extra satiny texture that came out nicely and I think I’ll use for the outside of pots I want to feel nicer in the hands.

A whole range of my tests involved using SiC to create reduction effects, pulling oxygen molecules bonded to iron from the glazes at high temperatures like flame does in an atmospheric kiln. None of those tests went well, too much SiC and possibly, the mesh size was too large. I have some which is a good deal finer that I’ll test in the next round

I was throwing mugs the second half of the day. Working on dialing in the small mug shape. There are two contenders, I love them both. One with a cleaner profile, the other with the synched middle that I’ve been drawn to in all this work. Photos of all that later.

Finished making glaze tests for the first run of the kiln. There are 54 in total, all variations on a single base glaze I used for the first round of pots in December. It’s a recipe of Derek Au and can be found here.

The variations test different techniques for getting a more matte or satiny surface, as well as lots of different oxides for color, including cobalt, copper, zirconium, rutile, tin, and iron. I’m also testing many of these glazes with the addition of Silicon Carbide. Part of Silicon Carbide’s chemistry is that it grabs oxygen from its surroundings at high temperatures, leading to reactions in glazes like the reduction you’d get in an atmospheric kiln. Or so I’m told. We’ll see how this actually goes tomorrow or the next day.

I cleaned up the studio (sort of) after turning the kiln on and left it to get toasty. Then I went back later in the evening to check on it. The lid doesn’t fit too well so there is a lot of leakage of heat from the top. But it seemed to be fine and was almost at top temp right on schedule. The studio was very smoky though, so I left a window open and I’ll plan on having a little pastoral coffee moment in the grass outside the studio in the morning while I let it all air out.

the glowing kiln over 2000 degrees! It really should not be letting out that much heat/light.

the max temp is 2215 for this firing, so, despite the leaky kiln, we seem to be doing okay to reach that

the tiles pre firing...